Contract Packaging Guide

Leave a Comment

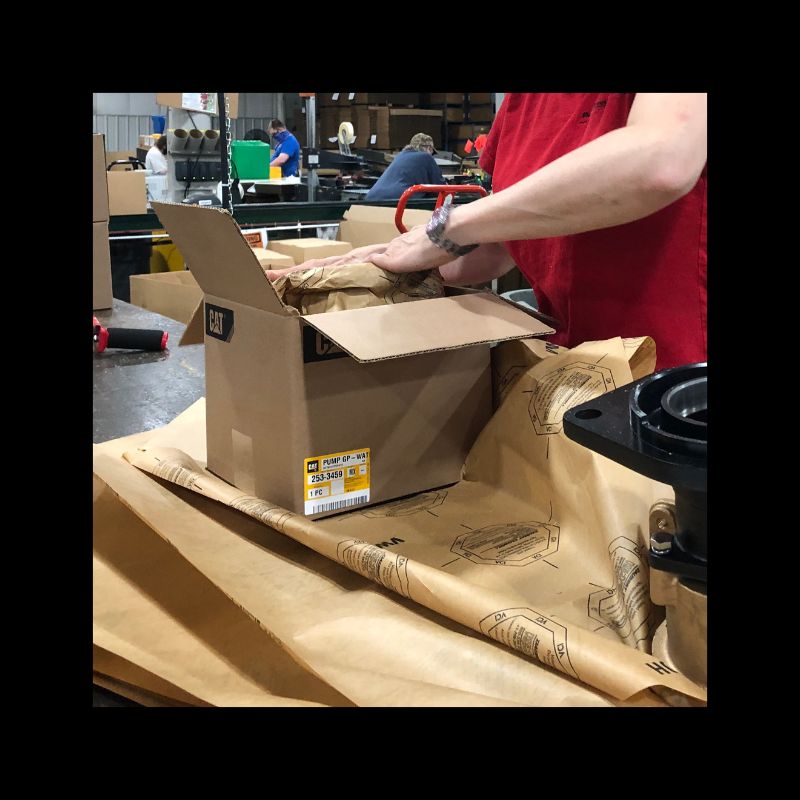

Contract packaging companies provide valuable services to a wide range of industries, packaging many types of products such as various consumer goods, hardware, pharmaceuticals, electronics, food, beverages, construction materials and so much more. Peoria Production Solutions has provided quality contract packaging services for more than 80 years. In addition to customized, quality packaging services we provide on-time delivery with wrapping, palletizing, and shipping to your specifications.

We offer a wide range of contract packaging, packing, repackaging, and secondary packaging solutions, as detailed in this Contract Packaging Guide.

Contract Secondary Packaging Solutions

Outsourcing your secondary packaging processes to a contract packaging company can provide many benefits over performing packaging in-house. PPS offers a wide range of quality secondary packaging processes with a skilled workforce and strict quality control. As a not-for-profit, fully sustainable company we provide the most cost-efficient secondary packaging services available.

Our secondary packaging services can provide added layers of protection, increase your branding, and make your products ready for display. We have the capacity and resources to customize packaging processes to meet your needs with full quality control and product traceability. Types of secondary packaging processes we are experienced with include the following:

● Kitting and assembly – kitting and assembly provide many benefits to a wide range of industries and applications with kitted products organized and available for use on a manufacturing line or for direct retail sale.

● Clamshell packaging – clamshell packaging can be performed with a variety of materials such as cardboard, phone, or see-through plastic for visibility.

● Club packs – club packs display products for retail sale and often require visible information such as lot or date codes.

● Variety packaging – we offer quality variety pack packaging customized to showcase your featured items in one newly assembled package.

● Gift set packaging – gift set packaging provides customized packaging solutions with a variety of materials, colors, and designs, and labeling to showcase specific products.

● Bag filling – filling bags and pouches is a good option for flexible packaging solutions. PPS offers quality bag filling with automated backfilling equipment, feed systems, and scales for high accuracy.

● Point-of-purchase displays – point-of-purchase, POP, displays are packed with a wide range of materials with aesthetically appealing designs geared toward a positive consumer experience and increasing brand awareness.

● Cello wrapping – PPS offers cello wrapping services, tightly wrapping products and biodegradable cellophane and heat sealing for a protective and neat closure.

● Repackaging – repackaging products quickly to customer specifications is often required to meet production deadlines.

● Fulfillment – PPS provides shipping and fulfillment solutions with our Midwest central location near Chicago O’Hare International Airport and the toll road, and our state-of-the-art facility with 15 shipping and receiving docks.

● Palletizing – PPS is experiencing palletizing your products in the most efficient method, stacked and wrapped for safety and quality product delivery.

Peoria Production Solutions provides these contract packaging and secondary packaging solutions and others, customized to meet your specific requirements. We differ from other packaging companies in our commitment to customer success and our skilled workforce. As a fully sustainable, not-for-profit contract packager, we offer high-quality packaging services at the most cost-efficient solution for our customers.

PPS has been an industry-leading contract packaging company for more than 80 years, embracing growth through research, development, and innovation since our founding in 1941. We offer a wide range of secondary and contract packaging services, customized to meet the needs of companies of all sizes including Fortune 100 OEMs, and small and midsize businesses. Contact us to learn how to improve your packaging process with quality and cost-efficient contract packaging services.

Types of Paperboard Materials For Blister Packs

Leave a Comment

Blister packs are a type of packaging that feature preformed visible cavities, a shell, or a pocket, most often in see-through material that is adhered to a coated paperboard, allowing consumers to see what is inside. This preformed plastic pocket is usually heat sealed to the paperboard or foil backing. It can be a daunting task to choose the best type of paperboard backing for blister packaging with many options to choose from in many factors to consider.

Considerations When Choosing Paperboard Backing for Blister Pack

Some of the most important considerations when evaluating paperboard backing for blister packs include the shape of the product, the design, the branding, any tooling or prototyping necessary, printing, and sealing. Different types of blister packs include full-face blisters, footed blisters, face seal blisters, and combo blisters.

Types of Material Available for Paperboard Blister Backing

The blister package contains two basic components, the plastic front with pockets and the paperboard backing that typically contains most of the branding message and retail information. There are many different types of material available for paperboard backing, some of the most common types include:

- Clay-coated board (C1S/C2S)

- Solid bleached sulfate (SBS)

- Recycled paperboard

- Tear-resistant board

- Laminated board

- Chipboard

Among these, two of the most popular choices are the Clay coated board (C1S/C2S) which is a type of SBS and recycled paperboard. This is mainly due to affordability, availability in the market, and packaging capabilities.

Clay-Coated (C1S/C2S) SBS

The difference between C1S and C2S is that C1S is Clay coated only on one side which provides a shiny, smooth surface while the back surface has a matte surface. C2S means the paperboard is Clay coated on both sides to provide a shiny, smooth surface on both the front and the back. There are advantages of using each type as Clay coated SBS provides many benefits for packaging, printing, sealing, and point-of-purchase (POP) displays.

Benefits of Clay-Coated Board (C1S)

Packaging – works best for Face-Seal Blisters

Printing – enhances the visual appearance of images on the shiny, coated side with minimal ink absorption. The matte finish on the uncoated side has greater ink absorption and reduced visual image quality.

Sealing – the best seal is on the clay-coated side only

POP Display – a good choice for crisp design with vibrant colors on the front and plain printing on the back such as UPC codes or simple text in black ink.

Benefits of Clay-Coated Board (C2S)

Packaging – the best choice for trapped blisters or back seal, when two cards are sealed together.

Printing – the glossy, shiny surface on both sides enhances visual images with minimal ink absorption on both sides.

Sealing – provides good sealing for both sides

POP Display – allows for vibrant colors and design with crisp branding on both sides

Depending on the considerations listed above such as the type of blisters0—–rt54444, printing requirements, and sealing options, both C1S and C2S provide many benefits although the double-coated C2S will cost a bit more than C1S.

Benefits of Recycled Paperboard

Recycled paperboard also provides many benefits with a high percentage of recycled paper content; it is a much more sustainable packaging option. Recycled paperboard provides many benefits such as:

- Sustainability – companies that choose recycled paperboard for their blister pack backing are choosing a product manufactured with more sustainable materials and processes to improve their corporate responsibility.

- Product lead time – recyclable products are often more readily available which can lead to improved production lead time.

- Various packaging styles – recycled paperboard is available in many packaging styles, often used for Trapped Blisters with two cards sealed together or Face-Seal blister packs.

- Sealing – typical sealing methods of heat sealing are best on the front side of recycled paperboard.

Consulting with an experienced contract packaging company will help you to know your options to choose the most effective and cost-efficient type of material for your blister packs.

PPS Is an Experienced Contract Packaging Company

Peoria production solutions, PPS, is an experienced contract packaging company providing packaging, repackaging, packing, bag filling, and palletizing services. PPS is experienced in the many types of packaging materials and offers a wide range of secondary packaging solutions such as:

- Blister packs

- Club packs

- Clamshell packaging

- Point-of-purchase (POP) displays

- Variety pack packaging

- Gift set packaging

- Cello wrapping

PPS offers these secondary packaging solutions along with many other production services to function as an extension of your production team. We offer these many packaging and repackaging services including kitting and assembly, all customized to meet your specifications.

PPS is a leading contract packaging company offering a wide range of services with more than 80 years of experience. We follow strict quality policies as part of our ISO9001:2015 registration, delivering quality products on time. Contact us to learn more about improving your packaging process with tips from contract packaging experts.

Kitting for Automotive Parts Provides Many Benefits

Leave a Comment

Kitting is a very important process that improves efficient assembly and inventory management in many manufacturing applications. Kitting provides many benefits when a small number of components are needed to create an assembled product or for specific made-to-order items that are customized by consumers.

Kitting Versus Subassembly: Not the Same Thing

Kitting and subassembly are two terms that are sometimes used interchangeably, although they are two different processes. Kitting is often performed prior to a subassembly process, where the numerous parts that are needed for the subassembly are provided into a convenient kit, helping to aid the efficiency of the next process. This is sub-assembled component is then often transferred on down the line to the next step in the production process to be assembled onto yet another larger piece or the final product.

This is a very common practice in automotive manufacturing facilities, where several subassemblies must be produced prior to installation into a final automobile. Even before the advent of smarter, electric vehicles, computer chips, and computer-driven technology had become an important component of automobiles. Electronic kit assembly provides many efficiencies in automobile manufacturing as well as other production processes.

Kitting in Automobile Manufacturing: In-House and Outsourced

Kitting in manufacturing can be performed in-house in a manufacturing facility, in a different location or right next to the assembly line where an assembled component is needed. This requires the automotive company to set up a kitting location and pay workers to perform the job. Some companies have realized many benefits by outsourcing kitting to an experienced company that provides electronics kitting services.

Kitting in manufacturing makes sensewhen many components must be assembled to create a new subassembly, kitting also makes sense when manufacturers have limited floor space for conducting kitting operations. Kitting of any type of components including electronic parts provides many benefits for the operator to have exactly what they need when they need it, and outsourcing benefits the company with efficient delivery of kits ready for their production line.

Kitting in automobile manufacturing is a common practice when many assemblies must come together to create one new vehicle. Kitting benefits the production of various automobile assemblies such as:

- Steering wheel assembly

- Dashboard

- Seats

- Speakers

- Trim

- Upholstery

- Mechanical components (brakes, throttle bodies, etc)

- Doors and windows and all the buttons and knobs that go in them

Kitting helps to speed up the assembly of these types of components and is important in the automotive industry for efficiency and inventory management.

Benefits of Outsourcing Kitting in the Automotive Industry

Optimizing capacity, storage, and manufacturing space

Outsourcing kitting processes provides many valuable benefits to automotive OEMs because they can free up their own floorspace to focus on their niche manufacturing, perhaps even install new assembly lines, without dedicating space and labor to assembling kits.

Improved inventory management

Most automotive OEMs practice just-in-time (JIT) inventory management for efficient inventory turnover which significantly reduces costs and improves financial health. Just-in-time delivery of kitting components helps to keep automotive assembly lines running efficiently, without the need for massive floor space to store numerous parts and components.

Improve productivity and profitability

Working with an experienced contract kitting provider and one with experience in electronics kitting services can drastically improve OEM’s productivity and profitability

PPS Offers Quality and Experienced Kitting and Electronic Kitting Services

Peoria Production Solutions, PPS, is an experienced contract kitting company with more than 80 years as an industry leader providing kitting, electronic kitting, assembly, and other secondary production services. We partner with our customers to customize kitting and assembly needs processes to meet their needs with high-quality products delivered on time. As a fully sustainable not-for-profit company, PPS succeeds only when our customers succeed, PPS is in the unique position to deliver high-quality at the most affordable costs in the industry.

PPS is a leading industry provider of kitting and electronic kitting services, providing on-time delivery of high-quality products with full lot code tracking for complete accountability. We provide kitting services as a valued supplier to some of the largest Fortune 100 manufacturers in the country and improve efficiencies for small to midsize companies. Contact us to learn more about improving your manufacturing process with efficient and cost-effective kitting and electronic kitting services.

Custom Repackaging Solutions For Custom Problems

Leave a Comment

Companies are getting creative with their packaging processes, looking for ways to improve efficiencies and save money. Some companies have switched from corrugated boxes to reusable totes, for example, when shipping products to suppliers who may perform assembly or secondary production work and then use the same totes to return products. As no two factories or warehouses are alike, companies are realizing that they can shape their packaging and shipping processes to meet their own specific needs based on their industry, their purpose in the marketplace, and their geographic location.

According to a recent Smithers analysis, the packaging industry broke the $1 trillion mark in 2021 and is slated for a study compound annual growth rate (CAGR) of 3.9% through 2026, reaching an estimated $1.22 trillion. Packaging is big business and it is a big part of a product’s expenses throughout the entire product lifecycle.

Customizing the type of packaging and the way companies perform the packaging of their products can drastically improve operational efficiencies, productivity, and profitability. Many companies are realizing that outsourcing their packaging to an expert contract packager is actually much more affordable than performing this process in-house.

The Benefits of Outsourcing to a Contract Packaging Company

Many manufacturers continue to perform their processes the same way they always have, from production to packaging, to inventory and/or shipping. This makes sense for some applications, but for others that invest in continual improvement and look for innovative ways to improve their processes, outsourcing packaging to a secondary packaging company has proven to deliver many benefits.

When companies outsource packaging to an experienced packaging provider, they can free up a lot of floor space in their own facility and eliminate packaging labor expenses. Additionally, an experienced contract packaging provider will ensure a quality packed product with experience in using a variety of materials. Oftentimes, contract packaging companies are aware of innovative materials such as flexible packaging bags, or pouches that can save companies a lot of money over rigid packaging materials.

Contract packagers that also perform assembly provide added value, as manufacturers that need to assemble components can simply ship everything to one supplier who will assemble and repackage components, returned and ready for stocking or delivery.

PPS Provides Customized Assembly and Packaging Solutions

Peoria Production Solutions, PPS, has been providing contract assembly and packaging solutions for more than 80 years. PPS is a leading contract packaging company and provider of secondary production solutions such as assembly and kitting with experience in a wide range of packaging materials. We follow strict quality policies as part of our ISO9001:2015 certification and utilize Enterprise Resource Planning, ERP, software to track all incoming and outgoing materials.

PPS has the capacity and experience to customize your packaging needs for the most efficient and cost-effective process. We are experienced in a wide range of packaging services including:

- Secondary

- Repackaging Services

- Club Pack

- Shrink Wrap

- Gift Set Packaging

- Palletizing

- Clamshell

- Auto Bagging

- Flex Pack

- Bag Filling

- Labeling

As a fully sustainable not-for-profit company, we are in the unique position to provide high-quality packaging solutions at the most affordable costs in the market. PPS is committed to total customer satisfaction and improving your secondary production and packaging processes, acting as an extension of your team.

PPS offers high-quality, customized secondary production and packaging solutions to meet your specific requirements. We invest in our staff with ongoing training who are skilled in using many of our automated solutions to meet your delivery schedules on time. Contact us to learn more about improving your packaging process with customized solutions to meet your unique specifications.

Improve Shipping with Flexible Packaging: Top 5 Benefits

Leave a Comment

The type of packaging that companies choose for their products plays many important roles throughout the entire operational supply chain. Packaging is an important factor in marketing products to consumers with appealing aesthetics but is also a critical factor when shipping and storing products and is often one of the largest expenses factored into an item’s production lifecycle.

Making the switch from rigid packaging to flexible packaging can provide significant improvements to a company’s operational efficiencies and bottom line, with the top 5 benefits including:

- Enhanced durability

- Product preservation and extended shelf life

- Optimized shipping space

- Greater product-to-package ratio

- More sustainable packaging and shipping

Flexible Packaging Provides Enhanced Durability

All types of products are damaged every day during shipping which leads to losses of damaged products, a waste of fuel delivering damaged goods, and added costs for reshipping the same products. Packaging materials like corrugated boxes and even dent-prone types of aluminum cans can still experience damage during shipping. Flexible packaging, however, is designed to absorb impact better and is non-breakable. Flexible packaging can be custom designed to incorporate multiple layers depending on the level of protection needed for the product.

Product Preservation and Extended Shelf Life

Flexible packaging materials have the ability to preserve products and extend shelf life. Many types of products benefit from packaging that resists corrosion, oxidation, and moisture, which corrugated and other packaging materials provide limited protection against. Flexible packaging such as stand-up pouches and powder bags has the ability to preserve products with air-tight seals and protective coatings, extending product quality and shelf-life.

Optimized Shipping Space

Stacking boxes on top of skids is the ‘way it’s always been done’ for packaging and shipping a wide variety of products. This often requires dunnage such as air-filled bags, Styrofoam, or wadded-up paper to prevent products from slipping during transit. Filling space with added products costs money and is wasteful in many ways.

Flexible packaging optimizes shipping space with less empty space and no need to pack protection around products in boxes. Flexible packaging can cost much less to ship when rates are based on box dimensions with no need for filler material. This allows for shipping a greater quantity of product on the same truckload, drastically improving logistics and reducing carbon emissions.

Greater Product to Package Ratio

Flexible packaging provides a greater product-to-package ratio, with more product compared to the packaging material used. This means less waste and less resource consumption. A higher product to package ratio also means there is less weight which can reduce shipping costs, and more products can be stored in the same space.

More Sustainable Packaging And Shipping

Flexible packaging is a more sustainable option than other packaging methods, providing sustainability throughout the entire lifecycle, according to the Flexible Packaging Association. Flexible packaging results in less greenhouse gas emission, less fossil fuel usage, less transportation-related energy, and less environmental pollution.

With all of these benefits, companies that make the switch from rigid packaging to flexible packaging can significantly reduce their packaging expenses and improve capacity in their warehouse or facility. Working with an experienced flexible packaging provider helps companies to realize maximum benefits and improvements to their operational efficiencies.

PPS Is a Flexible Packaging Provider

Peoria Production Solutions, PPS, is an experienced contract packaging company offering a wide range of packaging solutions including flexible packaging. We provide secondary packaging solutions to some of the largest corporations in America and improve efficiencies for companies of all sizes. Our skilled staff specializes in wrapping, bagging, filling, and packaging, with high attention to detail and quality-driven policies based on our ISO9001:2015 registration.

PPS excels in meeting our customer needs with high-quality and cost-efficient packaging solutions. We offer packaging, kitting, wrapping, assembly, sewing, and more to act as an extension of your production team. Contact us to learn more about the many benefits flexible packaging can provide to your company when working with an experienced flex packaging provider.