Are You Over Packaging Your Products?

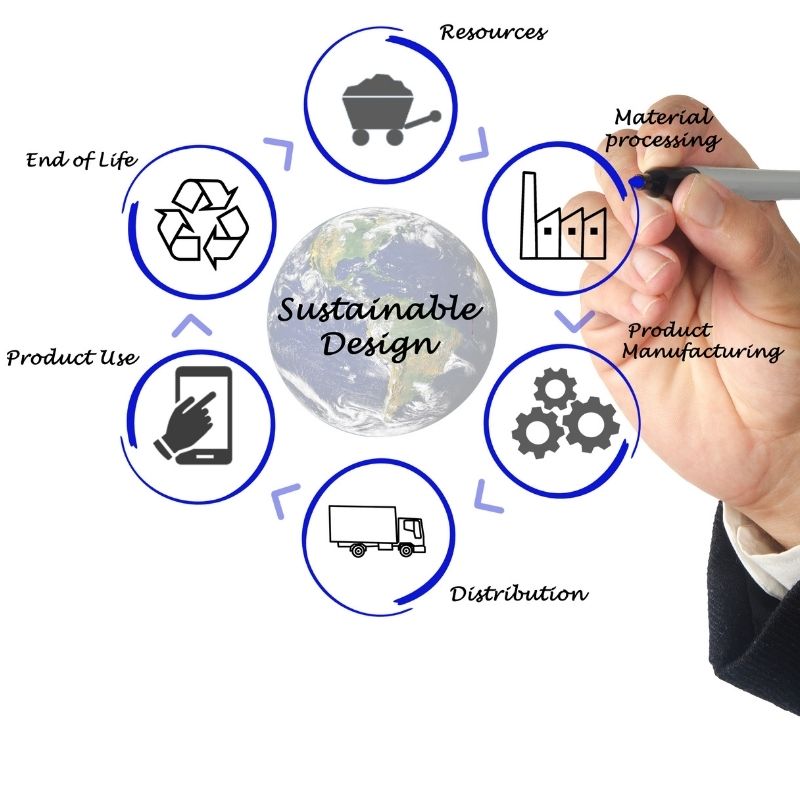

There is a big difference between over packaging and under packaging products, and somewhere in the middle is the perfect balance with an optimized packaged item. Depending on who you talk to, about half… Are You Over Packaging Your Products?