Nutraceutical Contract Packaging: Comprehensive Solutions for a Growing Industry

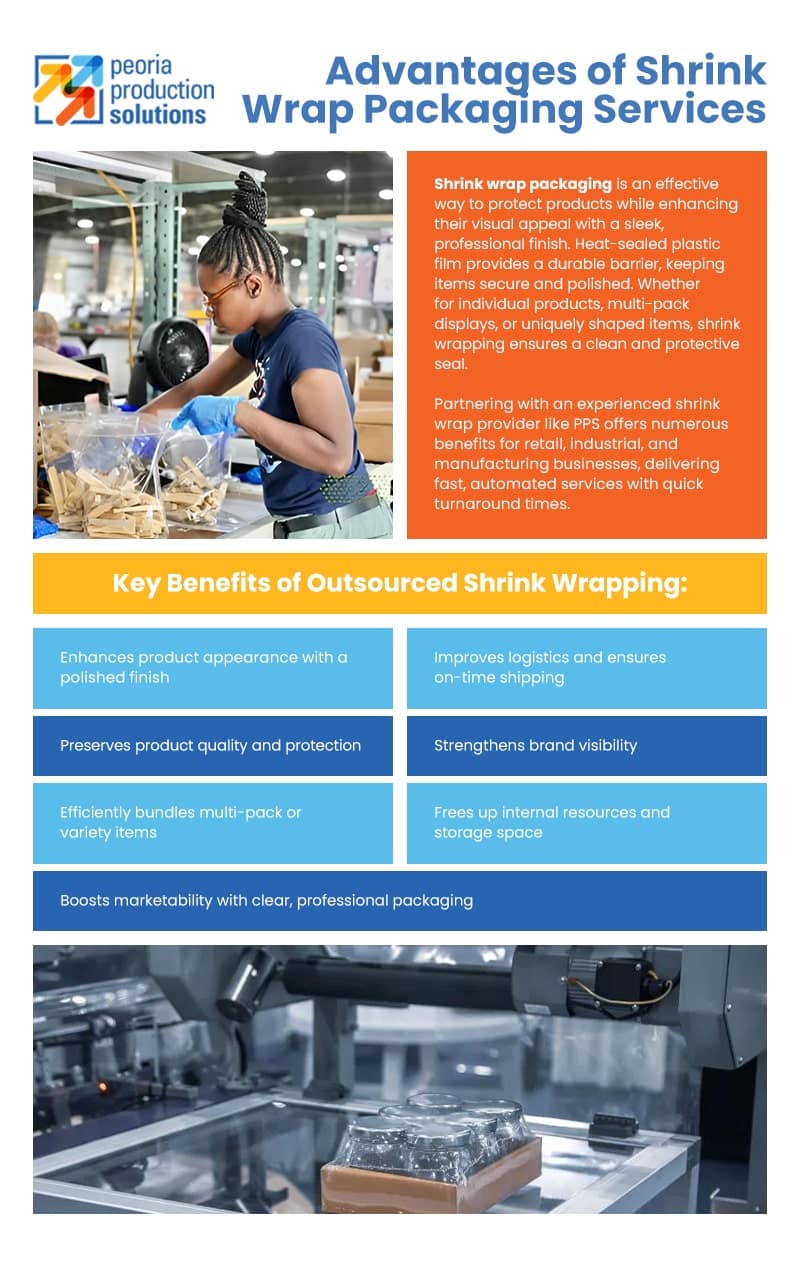

Peoria Production Solutions (PPS) provides specialized nutraceutical contract packaging, kitting, and assembly services for companies seeking efficient, compliant, and high-quality solutions to support growing product lines. Nutraceutical Contract Packaging: Comprehensive Solutions for a Growing Industry… Nutraceutical Contract Packaging: Comprehensive Solutions for a Growing Industry