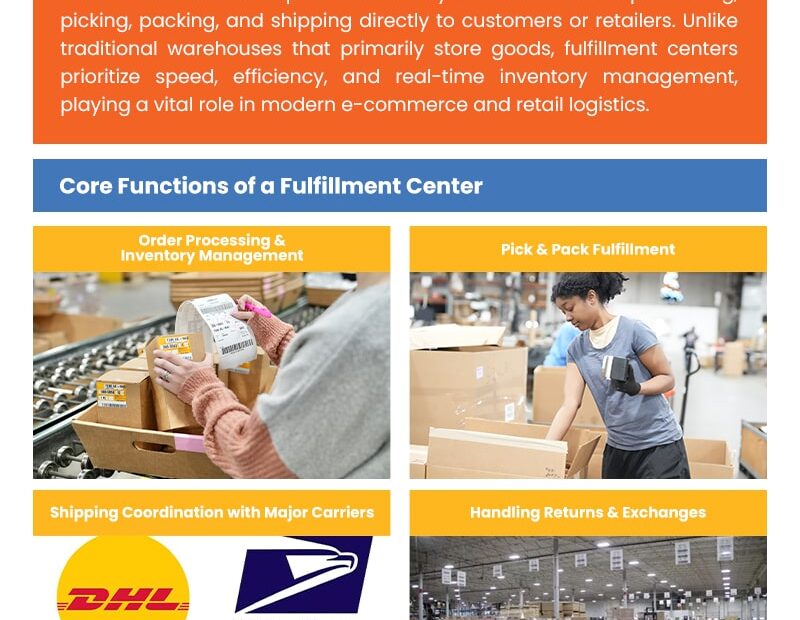

What Is a Fulfillment Center- Infographic

While fulfillment centers and warehouses might appear similar, they play very different roles within the supply chain. It’s essential for businesses to understand these differences when selecting the best option for inventory storage, distribution, and… What Is a Fulfillment Center- Infographic