Packaging Is a Constant, Critical Process for All Businesses

Packaging might be one of those elements that are taken for granted, performed the same way it’s always been done. Most businesses are busy manufacturing or promoting their niche products and forget to evaluate their packaging process periodically. Many companies continue to purchase the same types of corrugated boxes in the same sizes from the same supplier and perform in-house packaging the same way.

This consistent demand for packaging should not be overlooked and is one of the best places to start when evaluating your processes and supply chain for cost savings.

Make Smarter Packaging Choices

Instead of evaluating your packaging process only to cut costs, business managers should focus on making smarter packaging choices. Packaging always has to meet the most important demands, such as product protection, brand awareness, and traceability. Not all packaging expenses are tied up in material, evaluating the entire process is critical to recognizing areas for improvement.

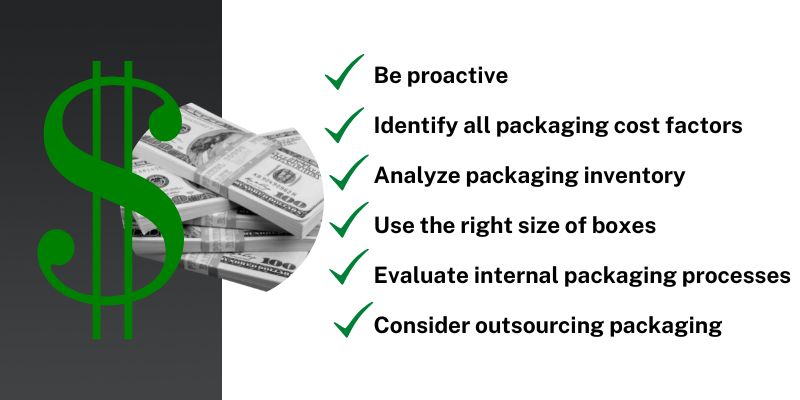

Some things to do to make smarter packaging choices include:

- Be proactive – don’t wait until you experience skyrocketing costs for your supplies.

- Identify all packaging cost factors – evaluate all cost factors, including material, delivery times, shipping costs, labor, and capacity.

- Analyze packaging inventory – make sure your packaging fits your products without excessive need for dunnage. Consider using padded envelopes instead of boxes when possible.

- Use the right size of boxes – most carriers like UPS and FedEx base pricing now on dimensions in addition to weight. Using oversized boxes is a waste of space and money.

- Evaluate internal packaging processes – is your packaging process optimized for efficiency? Streamlining work processes with an organized flow of materials, without backtracking over workstations to get your products from production, to packaging and shipping, can reduce workspace, free up capacity, and cut costs.

- Consider outsourcing packaging – evaluating contract packaging companies, and ask for assistance in evaluating your total packaging costs compared to your current expenses. In the past, companies may have considered contract packaging unaffordable, although contract packagers today are a valuable addition to many supply chains.

Contract Packaging Provides Many Benefits

Working with a contract packaging company provides many benefits over companies performing packaging in-house. Contract packagers offer expertise in the various types of packaging materials and can make suggestions for types and sizes of boxes and other packaging materials that can meet a company’s needs while providing cost savings.

One of the greatest advantages of working with a contract packaging company is the ability to free up floor space at current facilities. Shipping product in bulk to a contract packager allows companies to focus on their niche product production and receive their products back ready for direct shipment or sale. This saves on internal packaging labor and allows companies to grow with an expert packager fulfilling this very important role.

PPS Offers Quality Contract Packaging Services

Peoria Production Solutions, PPS, offers a wide range of quality contract packaging services for all types of companies. PPS is an expert Midwest contract packaging company with more than 80 years of experience in helping companies to meet production goals. Our contract packaging services include primary and secondary packaging, repackaging, packing, kitting, assembly, auto bag filling, cello wrap, and flexible packaging and palletizing services. We also provide electronics kitting and government sewing contract services.

PPS is a fully sustainable, not-for-profit contract packaging company focused on total customer satisfaction through employee development and training. We follow strict quality policies as part of our :

Peoria Production Solutions, PPS, offers a wide range of quality contract packaging services for all types of companies. PPS is an expert Midwest contract packaging company with more than 80 years of experience in helping companies to meet production goals. Our contract packaging services include primary and secondary packaging, repackaging, packing, kitting, assembly, auto bag filling, cello wrap, and flexible packaging and palletizing services. We also provide electronics kitting and government sewing contract services.

PPS is a fully sustainable, not-for-profit contract packaging company focused on total customer satisfaction through employee development and training. We follow strict quality policies as part of our ISO9001:2015 registration and provide full material traceability with our ERP system. Contact us to learn more about how our contract packaging services can provide you with packaging cost savings.