Packaging labels do more than convey product information; labels play a critical role in compliance, traceability, and production efficiency. As manufacturers manage tighter timelines, smaller batch sizes, and growing SKU complexity, choosing the right labeling approach helps prevent disruptions and keeps operations running smoothly.

At Peoria Production Solutions (PPS), labeling is treated as a core extension of the production process rather than a standalone step after production. PPS supports manufacturers across industries such as food and beverage, education, pet care, retail, electrical, energy, healthcare, and general manufacturing, where accuracy, speed, and flexibility matter.

Common Packaging Labeling Options

What types of labels are commonly used in manufacturing? Manufacturers typically rely on several proven labeling formats, each suited to different packaging needs:

- Pressure-sensitive labels for flexibility across package shapes and short production runs

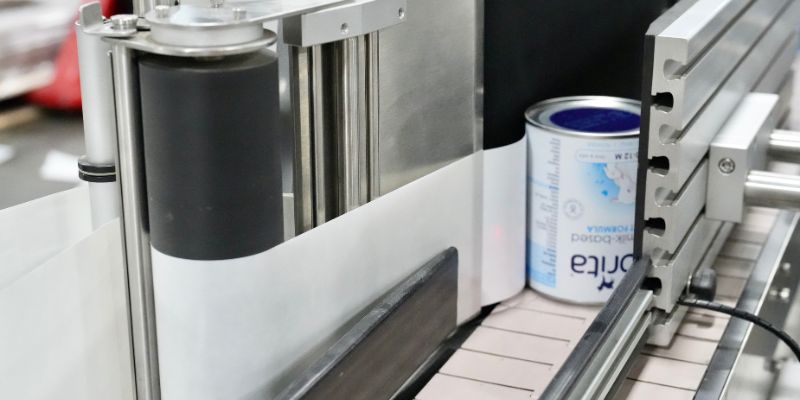

- Wrap-around labels for cylindrical containers that require consistent coverage

- Double-sided (front and back) labels to separate branding from regulatory or instructional content

- Relabeling solutions to support product updates, corrections, or market-specific requirements

These options allow manufacturers to match labeling methods to product form, regulatory requirements, and production volume.

Label Placement and Production Considerations

Why does label placement matter? Placement affects more than shelf appearance by directly impacting operations. Barcode orientation, regulatory visibility, and consistency all influence inspection, case packing, and distribution. Poor placement decisions can lead to scanning issues, rework, or delays during quality checks.

To create the best labeling solution, we consider package shape, surface material, orientation requirements, and compatibility with the full packaging processes.

Where Labeling Can Go Wrong

PPS takes pride in a quality labeling approach to avoid issues. Manufacturers with less experience or companies looking for a quick label can run into problems. A few common challenges include:

- Misaligned or inconsistent label placement that interferes with scanning or packaging

- Label-to-product mismatches during short runs or frequent changeovers

- Outdated label versions applied after regulatory or product updates

- Lack of quality checks, where errors are identified late in the process

These issues can slow production, increase labor costs, and create compliance risk, making labeling accuracy essential to overall manufacturing performance.

Labeling as Part of a Broader Packaging Strategy

Labeling can be even more effective when integrated with broader packaging activities such as fulfillment, assembly, and kitting. This approach supports both labeling and relabeling needs while reducing handoffs, improving accuracy, and keeping production moving efficiently, especially for short runs and complex SKUs. Check out our labeling services infographic for a helpful guide.

PPS specializes in custom service and offers no MOQs (minimum order quantities). Companies rely on partners with defined processes, inventory controls, and production-aware quality checks. PPS supports these needs with short lead times, low error rates, and thorough inventory verification, helping manufacturers stay agile and accurate.

Let’s Connect

The right labeling approach keeps products compliant, lines moving, and operations on track.

Let’s talk about how PPS can help you with effective labeling and move inventory with speed, consistency, and care. Contact us or request a quote

Stay up to date on industry insights by subscribing to our newsletter.