This article was published on May 11, 2021 and updated on February 21, 2023

Kitting and assembly services provide many benefits to original equipment manufacturers (OEMs) such as reducing internal assembly costs, improving quality, efficiency and profitability.

Kitting and assembly services provide many benefits to original equipment manufacturers (OEMs) and companies of all sizes.

What Is Kitting and Assembly?

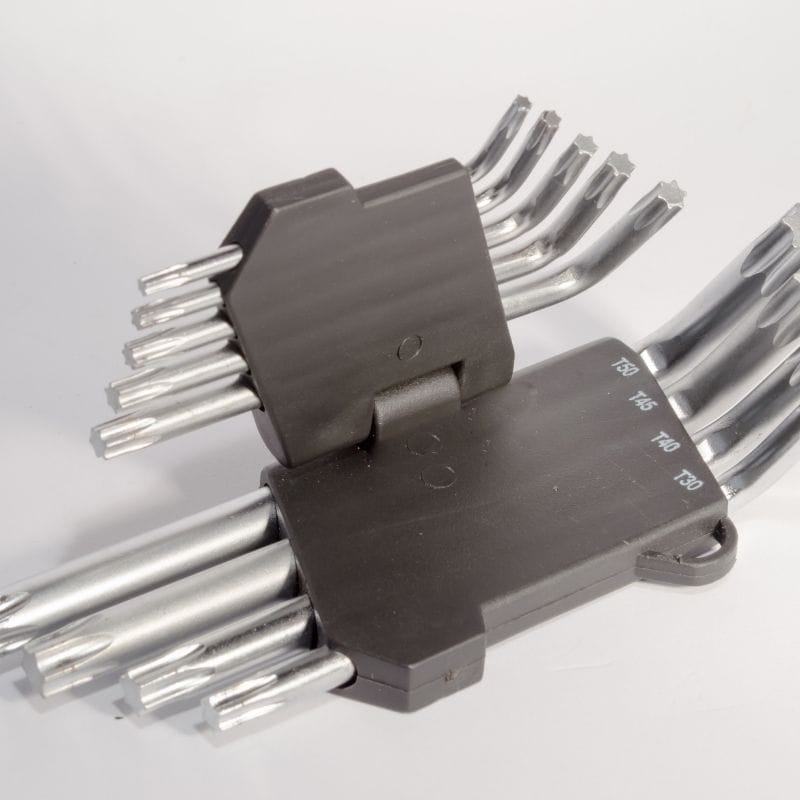

Kitting various products together is a process of combining items that complement each other or should be sold together and can be used in many industries for a wide range of products. Kitting in manufacturing is often used to have tools or parts that go together that are needed in a manufacturing process so that workers have exactly what they need, where they need them, and at the right time.

Kitting for retail products can include combining products in just about any industry where it makes sense to assemble items together. This includes:

- Arts and crafts

- Baby and children’s products

- Cosmetics

- Clothing

- Food and beverage

- Hardware kits

- Household goods

- Pet supplies

- Toys and games

- Personal care items like shaving kits, perfumes, or lotions

When kitting products together, all individual items and SKU numbers are combined into one kit with one SKU number, which simplifies inventory processes and can make accounting for small products much easier.

Assembly is another process that provides many benefits to manufacturers and retailers, as items that should be assembled prior to further processing are ready for the task at hand. Assembled retail items can make life easier for consumers and improve sales by providing convenience and value.

Benefits of Contract Kitting and Assembly Services

When companies outsource kitting and assembly services, they realize many benefits when working with an experienced contract kitting and assembly provider. Some benefits include:

Freeing up internal capacity – moving kitting and assembly services to a contract provider allows for more floor space for internal production needs. This allows companies to focus on their niche manufacturing and supports business growth.

Reduced labor expenses – companies can pay a contract kitting provider incentive pain internal labor and benefits, which can pay off in the long run, especially when companies experience high turnover rates and must continually train new employees.

Improved production flow – receiving kitting and assembled products from a contract provider can improve internal production flow and eliminate bottlenecks in the process by receiving exactly what you need when you need it.

Experienced Kitting and Assembly Provider

Peoria Production Solutions, PPS, offers contract kitting and assembly services and more than 80 years of experience. We provide kitting and assembly of a variety of products for many different industries and applications. We offer kits for manufacturing, kitting for retail goods, and contract assembly, including mechanical assembly and electrical assembly, with a highly skilled and trained staff.

PPS utilizes a variety of automated equipment, including auto bagging equipment, weighing and wrapping, and packaging equipment in our large, modern facility. We continually invest in our employees through training and cross-training programs and follow a strict quality policy as part of our ISO9001:2015 certification. We ensure complete accountability of all customer-supplied material with our Enterprise Resource Planning, ERP, the system with lot code traceability.

Peoria Production Solutions provides various secondary production requirements such as wrapping, packaging, bagging, filling, kitting and assembly to support your production needs and bring improvements to your internal operations. As a not-for-profit company, we are in a unique position to provide extremely competitive pricing to meet your budgetary goals. Contact us to learn more about how kitting and assembly can improve your processes when working with an experienced and quality-focused contract kitting and assembly provider.